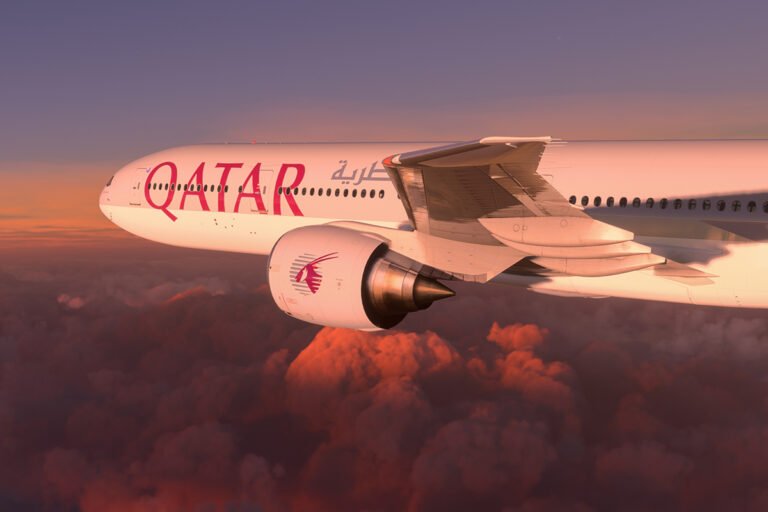

In a bold leap toward future-ready aviation, Qatar Airways has signed a milestone agreement to establish the Middle East’s very first digitally operated aircraft painting facility. The airline, known for its forward-thinking strategies and luxurious passenger experience, is now setting new standards in aircraft maintenance and design with this high-tech move.

The digital painting hub will combine automation, precision, and eco-conscious design, ensuring Qatar Airways aircraft not only perform flawlessly but also shine with pristine, perfectly applied liveries. This development is set to transform how airlines in the region approach aircraft maintenance, while reinforcing Qatar’s growing position as a regional aviation innovation leader.

The Future of Aircraft Painting Has Arrived

Aircraft painting is more than just aesthetics—it’s about aerodynamics, protection, branding, and operational readiness. The traditional process, often involving manual labor and long lead times, is now facing a technological disruption, and Qatar Airways is leading the charge.

The soon-to-be-unveiled digital facility will feature advanced robotic arms capable of performing intricate and large-scale paint jobs with unprecedented precision. High-resolution scanners and AI-powered design software will guide paint applications, significantly reducing waste, overspray, and human error.

With this facility, Qatar Airways expects to:

- Cut aircraft painting time by nearly 40%

- Reduce emissions through optimized energy use

- Offer aircraft finishes that are not only more durable but more visually stunning

It’s a significant evolution that positions Qatar as a serious player in the global aviation tech race.

A Major Win for Qatar and the Gulf Region

This project is not just a win for Qatar Airways but for the entire region. The Middle East, despite being home to some of the world’s busiest airports and most successful airlines, has long lacked a digital solution for aircraft livery applications. This agreement fills that gap—and then some.

By pioneering this facility, Qatar Airways is:

- Boosting local aerospace industry capabilities

- Creating high-skilled job opportunities for Qatari engineers and technicians

- Attracting international aviation partners and clients seeking premium aircraft servicing

The facility will likely serve as a regional hub, handling not just Qatar Airways’ fleet but also potentially servicing other carriers across the Gulf Cooperation Council (GCC), further enhancing Qatar’s role as an aviation powerhouse.

Innovation at Every Level

This agreement marks another stride in Qatar Airways’ broader push for digital transformation. The airline has already earned global praise for embracing artificial intelligence and biometrics at Hamad International Airport, its world-class hub in Doha.

Now, that same spirit of innovation is being applied to back-end operations. From customer experience to maintenance, every touchpoint in the Qatar Airways ecosystem is undergoing smart, data-driven transformation.

Here’s what sets this digital painting facility apart:

- Robotic Application Systems: Fully automated arms equipped with programmable nozzles that adapt to different aircraft models

- Digital Color Matching: AI-driven software ensures exact brand colors every time, regardless of weather or material

- Eco-Friendly Drying Chambers: Rapid and energy-efficient paint curing processes, lowering the environmental footprint

- Remote Monitoring: Supervisors can track progress and performance in real-time from anywhere, improving quality control and productivity

This isn’t just a paint shop—it’s a digital engineering marvel built to serve the aircraft of tomorrow.

More Than Just Looks: Sustainability Takes Flight

One of the most compelling aspects of this new facility is its alignment with global sustainability goals. Traditional aircraft painting is resource-intensive and generates significant waste. With precision tools and AI integration, Qatar Airways’ new approach promises:

- Up to 30% reduction in paint material usage

- Significant cuts in volatile organic compound (VOC) emissions

- Minimal water waste and chemical runoff

The airline has long committed to green aviation—from fleet renewal with fuel-efficient aircraft to carbon offset programs—and this facility is yet another statement of its environmental responsibility.

Designed for Growth, Built to Scale

Set to become operational by the end of 2025, the facility is being designed with scalability in mind. Phase one will focus on narrow-body aircraft, while subsequent expansions will include wide-body jets such as the Boeing 777 and Airbus A350—two workhorses of the Qatar Airways fleet.

Additionally, Qatar Airways is in talks to integrate complementary services such as:

- Digital decal printing

- Logo and branding customization

- Rapid touch-up stations for daily operations

This modular approach ensures the facility will remain adaptable to changing fleet demands and new technological advancements.

Job Creation and Knowledge Transfer

Qatar’s National Vision 2030 emphasizes diversification, technology leadership, and skill development. This initiative contributes directly to those goals.

The digital painting facility will generate:

- High-tech engineering roles in robotics, design, and automation

- Training programs for Qatari nationals in aviation maintenance technology

- Collaborations with local universities for R&D and talent sourcing

Moreover, the agreement includes a transfer of knowledge clause, ensuring that expertise developed through the project is retained within Qatar’s borders—nurturing homegrown aerospace talent and innovation.

A New Standard for Airline Excellence

For passengers, the change might be subtle but significant. Next time you board a Qatar Airways flight, that crisp, vibrant livery may well be the result of high-speed robotics and digital craftsmanship. Beyond looks, the benefits stretch into reliability, reduced downtime, and operational excellence—all factors that contribute to smoother, safer journeys.

This facility underlines a powerful message: behind the scenes of world-class service is world-class engineering.

Looking Ahead: What’s Next?

This initiative is just the beginning. Qatar Airways is reportedly exploring other digitally enabled MRO (Maintenance, Repair & Overhaul) solutions, from AI-powered engine diagnostics to blockchain-based parts tracking.

As demand for smarter aviation solutions grows, Qatar Airways is positioning itself as a thought leader not just in the skies—but on the ground as well.

Conclusion: Qatar Airways Is Repainting the Future

In an industry often slow to adopt change, Qatar Airways continues to prove it can break the mold. The agreement to launch the region’s first digital aircraft painting facility is more than just a maintenance upgrade—it’s a signal of bold intent, visionary thinking, and relentless pursuit of excellence.

From reduced emissions to faster turnaround times and unparalleled paint precision, this project reflects the airline’s dedication to sustainability, technology, and superior passenger experience.

The skies over the Middle East are about to look a lot more polished—and a lot more digital—thanks to Qatar Airways.

Do follow UAE Stories on Instagram

Read More: Unlock Your Best Self: Ultimate Self-Care Secrets in City Life