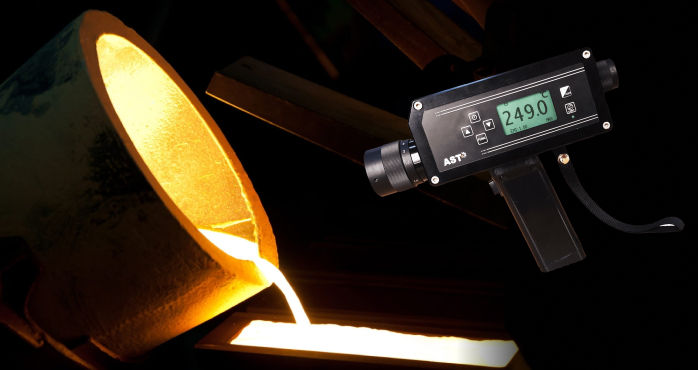

The thought of being able to gauge the temperature of a raging furnace or kiln used to melt glass in the UAE without physically being in contact with it. This is just what pyrometers do. According to the World Economic Forum, the manufacturing output of the UAE increased by 8.7 percent in 2022, which demonstrates the rapid transition of the country to the high-technology industry and automation. As this has grown, precise and safe temperature control has become necessary in steel, ceramics, and energy plants.

To the industry experts in the UAE, the knowledge of the way pyrometers operate is becoming extremely crucial. This guide will describe their principle of operation, application, and advantages, demonstrating how they enhance efficiency and minimize operational risks in high-temperature areas.

Understanding the Science Behind Pyrometers

A pyrometer is a kind of meter that gauges the temperature at a distance, using infrared radiation. It picks up the heat that an object emits and converts the heat into a temperature reading that may be useful in the safe and accurate monitoring of extremely high temperatures. Pyrometers are also suitable to be used on furnaces, kilns, or foundries since, unlike contact sensors, they do not need to be in touch with the surface, as they are considered to cause direct measurements to be hazardous.

The pyrometers are extensively applied in the steel, cement, and energy sectors in the UAE. Quick and quality outcomes realized by a pyrometer prevent overheating and increase the process safety as well as the product’s quality, which is the reason why it is included in the list of the primary items in the growing industrial automation of the country.

Key Types of Pyrometers Used in UAE Industries

The pyrometers used in different industries in the UAE differ in usage. The most important ones are provided below and can be discussed as the following benefits:

- The infrared pyrometers are widely applied in production lines since they are fast and accurate surface meters.

- Optical pyrometers are applied in the measurement of the very high wavelength of heat in plants composed of metal and glass.

- Ratio pyrometers can be used in dusty or smoky atmospheres due to their ability to compare the intensity of light.

- Pyrometers on fiber optics are the most suitable in high electromagnetic environments.

- The two-color pyrometers are superb in working with variable light or emissivity.

Major Industrial Applications of Pyrometers in the UAE

Industry standard uses include:

- At steel plants, the pyrometers can be used in the quality control of the molten metal temperature.

- Glass manufacturing would ensure that it has the correct melting and cooling processes to be strong.

- Cement Production: Heat generated in the kiln is checked to allow a gain of strength and reduction in energy wastage.

- The energy plants have a process of monitoring the temperature of boilers and turbines to ensure a consistent performance.

- They are applied in petrochemical plants to avoid overoperating and ensure that it is not a hazardous process.

Advantages of Using Pyrometers for UAE Industries

Implementation of pyrometers in industries in the UAE entails a series of advantages that ensure that operations of the industries are safe and efficient.

- They work without touching anything, and they are not harmful to the operator.

- They give very accurate results even at a very high temperature.

- They could be applied to hot and dusty places.

- They are equipped with instant readings, making them easy to use in making quick decisions.

- They help in saving energy that has been wasted in unwarranted heating.

Technological Advancements Shaping Modern Pyrometers

Automation and smart industry trends have led to the evolution of the principles of the technology of pyrometers. The latest developments are:

- Digital systems that display and document the real-time temperature.

- An IoT connection to enable remote monitoring of the industrial process.

- Greater intelligence to be smarter and more automatic.

- Minimal and lightweight models, which occupy a small space.

- Improved optical systems that are target-oriented.

Selecting the Right Pyrometer for UAE Applications

The type of localization, range of temperatures, and the nature of the process determine the choice of the correct type of pyrometer. Under the extreme conditions prevailing in the UAE, where heat, dust, and humidity are the order of the day, it is good to consider a well-calibrated and robust instrument that will work properly.

The steel or glass factories might wish to install permanent pyrometers in the factories, as an illustration, to ensure that they continuously monitor them, whereas the technicians might be required to check using handheld versions. A fingernail should select a pyrometer that has the capability of adjusting emissivity and that possesses a protective casing. Regular calibration and cleaning will ensure that it continues providing the same constant measurements and lasts longer under the severe conditions of the UAE industrial environment.

Reliable Partners for Precision Measurement

The tool is a must-have and a requisite tool in industries in extreme temperatures in the UAE, like those that provide safe and accurate temperature control. They are involved in terms of promoting efficiency, product quality, safety of work, reducing wastage of energy, and operating time.

The solution for companies that need quality and reliable pyrometers might be found in the UAE, at companies like Tempsens. They have been found to have accurate and long-lasting temperature reading instruments whose models are compatible with the rough work environments of the UAE. The choice of such reliable partners will give more control, fewer errors, and greater productivity in the industrial processes.

Do follow UAE Stories on Instagram

Read Next – Endowment District UAE: Mohammed bin Rashid’s Vision for Sustainable Giving